Plastic materials regeneration

3P Plast has over 30 years’ experience in recycling plastics from industrial scraps and post-consumer material, and in manufacturing and selling compound in polypropylene and polyethylene, exclusively for injection moulding.

PRODUCTION

The process takes place in two plants.

The first one is situated in Grantorto, where industrial scraps and other materials are sorted out and milled. The plant has a regrind-capacity of 2560t and can stock 3200t per month. The company is allowed for the waste treatment by the relating authorization.

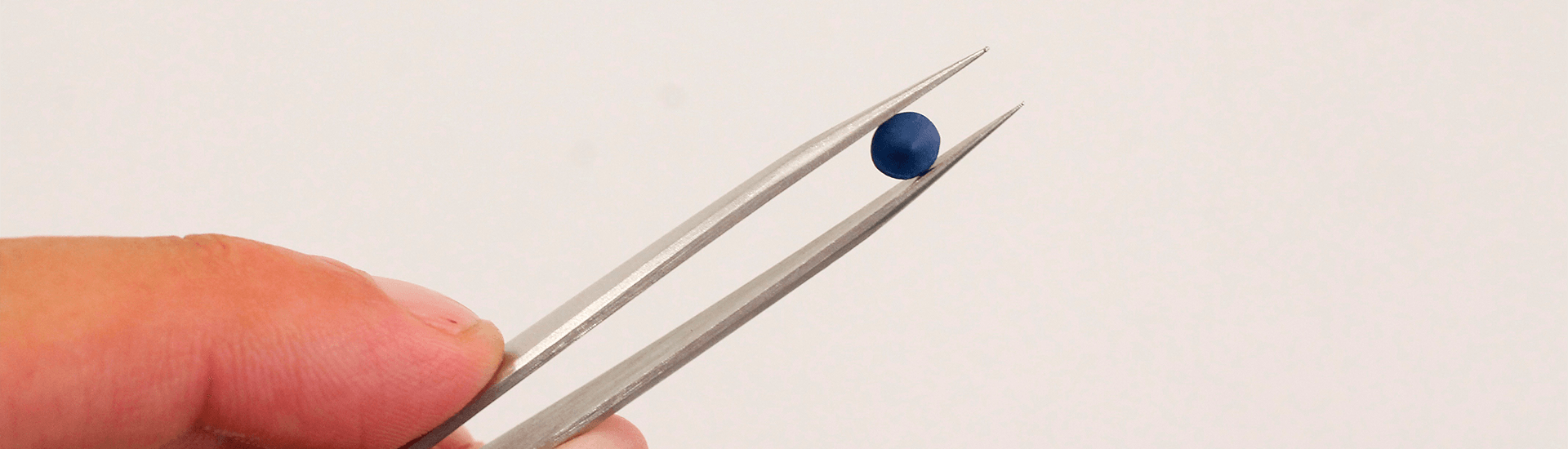

The second part of the process is carried out in the second plant in Fontaniva, the headquarters. The regrind material recycled in the first factory are processed into granules, colored by mixing masterbatch, through two extruders Maris, one single screw 150t and one twin screw Extruders 160t. The monthly production capacity amounts to 500t and its stocking one is 572t. Fontaniva’s plant handles dispatches as well.

3P Plast has got a careful and full vision of the process; the headquarter includes a technical lab, that analyses technical properties of the materials in entrance and compound batches in every single production phase, with equipment from the most important labels: Netzschfor “differential scanning calorimetry”, Amse tests “Izod impact testing” (resistance), Konica Minolta for the tonality color. All equipment is certificated and constantly updated.

The company meets the requirements of the norm ISO 9001:2015.

PRODCUTS

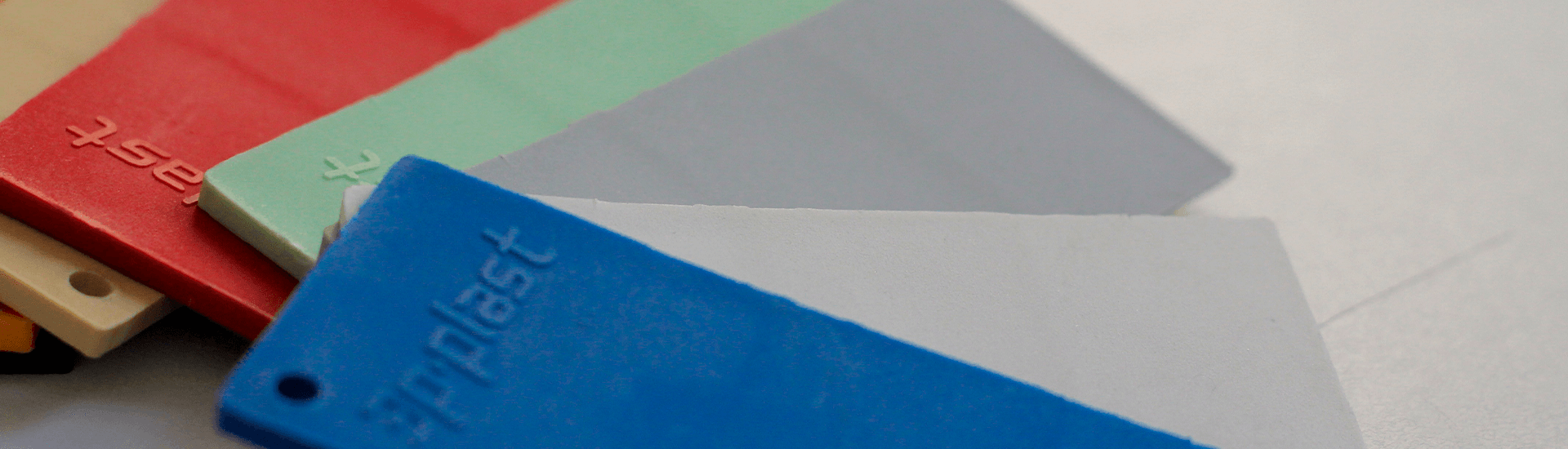

The range of materials (PP and HDPE) is from waste collection and industrial scraps selected per type to be processed.

Besides the following materials, 3P Plast can personalize according to the colors and technical data required by the client.